Share

During the process of making paper, corrosive gasses like hydrogen sulfide (H2S), sulfur dioxide (SO2), and chlorine (Cl2) are released. This, in combination with other environmental factors like temperature and humidity, can wreak havoc on the electrical equipment in pulp and paper mills. With unplanned downtime that can cost over $200K an hour, this can quickly turn into a worst case scenario. Purafil can help equip mills with the tools they need to monitor and maintain an acceptable environment.

Common Points of Failure

Pulp and paper mills day-to-day processes are often a major culprit in the breakdown of their electrical equipment. Due to these processes being an unavoidable part of production, it is important to monitor air quality and employ counteractive measures like custom scrubbers. Below is a list of common points of failure in pulp and paper mills.

The Electrical and Control Rooms for:

1. Wet and dry ends of the paper line2. Recovery boiler

3. Power house

4. Water treatment

5. Calciner

6. Digester control

Step 1: Diagnosis

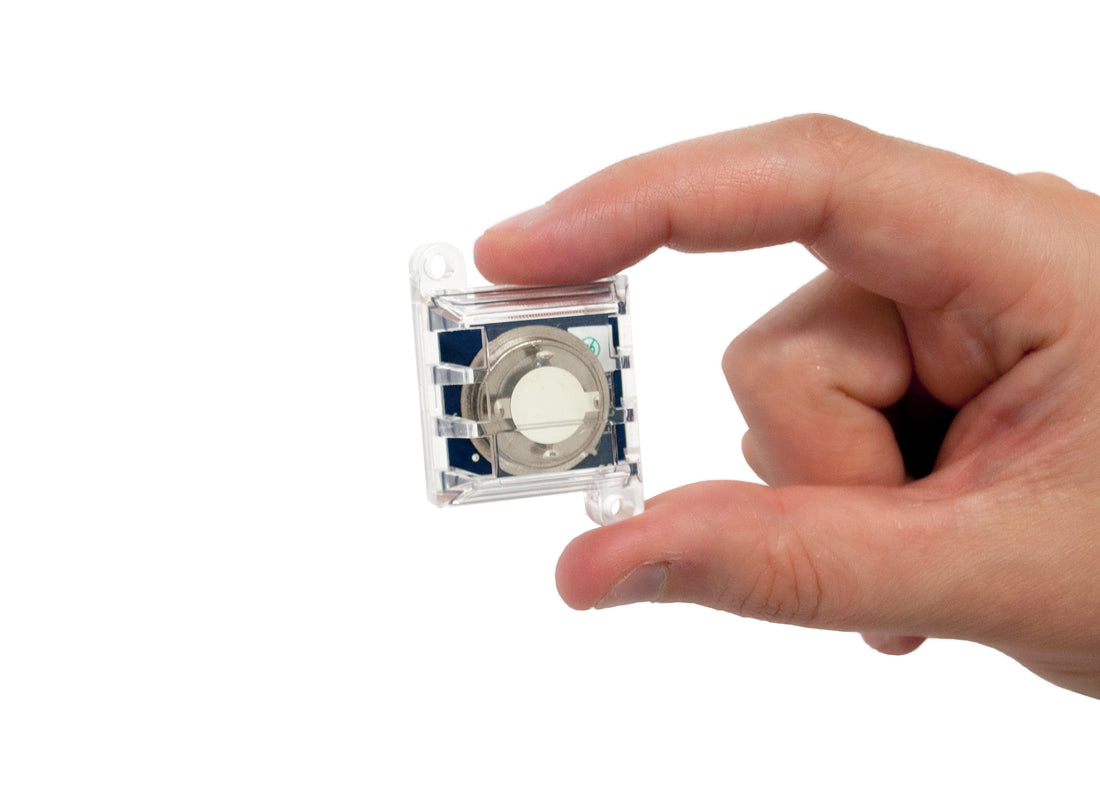

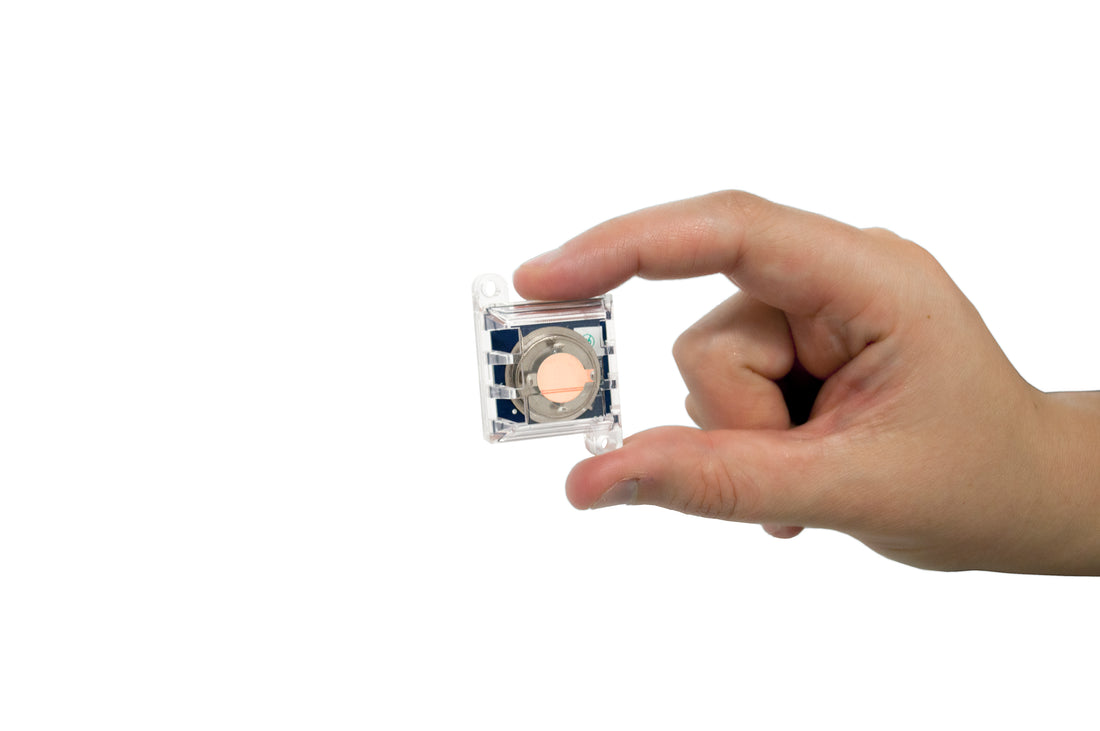

The first step any mill should take in the process of corrosion mitigation is diagnosis. Diagnosis will provide data on the state of your environment, which will influence what next steps you take. Diagnosis is done through reactivity monitoring. A common tool for this is Corrosion Coupons, which utilize copper and silver metal to determine the rate of corrosion in an environment over a 30-day period. With the Corrosion Coupon+, you can also get additional temperature and humidity information, which can help diagnose your source of corrosion. All of Purafil’s Corrosion Coupons follow the ANSI/ISA-71.04-2013 standard and come with a FREE corrosivity report from our lab. Users can also enjoy a uniquely digital experience with our online registration and coupon portal.

Step 2: Custom Solution

Once you receive your corrosivity report and have determined that your facility has a corrosive environment where critical electronics are stored, the next step in the process is finding a solution to combat it. A typical solution for corrosive air includes the installation of air scrubbers. From design to installation, Purafil comes alongside your team to tailor the right solution for your mill.

This includes working with our lab to determine the best filtration media (Such as PuraCarb®) to address the unique corrosive gasses in your environment, and our engineers to properly size the filtration equipment and seal the space, ensuring G1 corrosion free air.

Step 3: Analysis

Media Life Analysis is another complimentary service provided by Purafil’s corrosion control experts. Throughout the life of the scrubber, Purafil’s lab analyzes media samples from your air scrubber to determine the remaining service life. This helps you schedule and budget for when replacement will be needed, and ensure continuous corrosion control.

Step 4: Monitoring

After you have installed a custom solution in your space to mitigate it, you will want to regularly monitor to ensure your that all solutions are operating properly and no new problems arise unnoticed. The OnGuard Monitor is a real-time monitoring solution offered by Purafil. This versatile unit is unobtrusive and can transmit real-time data to your SCADA system via a 4-20 mA output signal, and is accessible over ethernet. You can also receive custom alerts right to your email to be warned when specific thresholds are met like temperature, humidity, and corrosion levels.

Maintaining a Corrosion Free Mill With Purafil

With Purafil, you can diagnose, monitor, and prevent corrosion before it wreaks havoc on your equipment — avoiding additional maintenance costs, repair expenses and unexpected downtime. Our 4 step process checks all of the boxes needed to maintain an environment that does not negatively impact electronic equipment. Contact us today to speak to a corrosion control expert. We look forward to helping you create your tailored corrosion solution!

0 comment