Share

ANSI/ISA-71.04-2013 is a set of industrial guidelines created to better regulate the protection of electronic equipment. The increasing complexity and decreasing size of electrical components, paired with the introduction of RoHS Lead-Free Initiatives made this standard necessary. Within this standard are the ISA Environmental Classifications. These classifications are used to define an environment’s severity by using corrosion rate data that has been gathered from a reactivity monitoring sample, like the copper and silver metal on a Corrosion Coupon or OnGuard Monitor. This corrosion is measured in angstroms, which is a unit of length equal to one hundred-millionth of a centimeter, 10−10 meter. This data is measured in such tiny increments because even small amounts of corrosion can cause failure in sensitive electronics.

Keep reading for a breakdown of the 4 ISA Environmental Classifications and a better understanding of what each level can mean for your facilities.

Severity level G1 – Mild

The first level in the ISA Environmental Classifications is G1 Mild. This level means that the corrosion rate is fairly low in the test space and is unlikely to pose a threat to equipment reliability.

What does this mean in scientific terms?

- Copper: Less than 300 Angstroms of corrosion was formed on this surface over a 30 day period

- Silver: Less than 200 Angstroms of corrosion was formed on this surface over a 30 day period. Silver is slightly more susceptible to corrosion and has a lower threshold than copper.

What are the potential next steps after receiving G1 results?

Due to a low corrosion rate, your facilities environment does not currently pose a threat to your electronic equipment. Next steps could include reactivity testing periodically with a corrosion coupon to ensure you are still maintaining that G1 environment.

Severity level G2 – Moderate

The second level in the ISA Environmental Classifications is G2 Moderate. This level means that the corrosion rate is measurable in the test space and has the potential to negatively affect equipment reliability.

What does this mean in scientific terms?

- Copper: Less than 1000 Angstroms of corrosion was formed on this surface over a 30 day period

- Silver: Less than 1000 Angstroms of corrosion was formed on this surface over a 30 day period

What are the potential next steps after receiving G2 results?

Due to a measurable corrosion rate, your facilities environment could pose a threat to your electronic equipment over time. It will be important to establish an ongoing monitoring strategy to ensure the corrosion rate does not worsen. It could be time to start considering the implementation of a corrosive air solution to improve your air quality.

Severity level G3 – Harsh

The third level in the ISA Environmental Classifications is G3 Harsh. This level means that the corrosion rate in the test space is concerning and poses an immediate threat to equipment reliability. There is a high probability that a corrosive attack will occur.

What does this mean in scientific terms?

- Copper: Less than 2000 Angstroms of corrosion was formed on this surface over a 30 day period

- Silver: Less than 2000 Angstroms of corrosion was formed on this surface over a 30 day period

What are the potential next steps after receiving G3 results?

Due to a harsh corrosion rate, it is highly likely your facilities environment will damage your electronic equipment. It will be important to consider which corrosive air solutions could be a good fit to combat poor air quality in your space. Once a working solution has been established, ongoing monitoring with tools like the OnGuard can help ensure your air quality is improving and your solution is continuing to work as expected.

Severity level GX – Severe

The fourth level in the ISA Environmental Classifications is GX Severe. This level means that the corrosion rate in the test space is extreme and it is unlikely equipment will survive unless it is specially designed and packaged to withstand severe corrosion levels.

What does this mean in scientific terms?

- Copper: Greater than 2000 Angstroms of corrosion was formed on this surface over a 30 day period

- Silver: Greater than 2000 Angstroms of corrosion was formed on this surface over a 30 day period

What are the potential next steps after receiving GX results?

Due to the severity of this corrosion rate, it is highly unlikely electronic equipment will survive in the environment. The installation of a tailored corrosive air solution will be necessary to avoid equipment damage in the future and combat environmental factors contributing to your GX results. Once a working solution has been established, ongoing monitoring with tools like the OnGuard can help ensure your air quality is improving and your solutions are continuing to work as expected.

Purafil Monitoring Solutions Can Help Identify ANSI/ISA-71.04-2013 Classification and Ensure Warranty Compliance

Purafil offers a full range of reactivity monitoring solutions to help better understand your environment and risk of corrosion. All monitoring results align with ISA 71.04-2013 severity level standards.

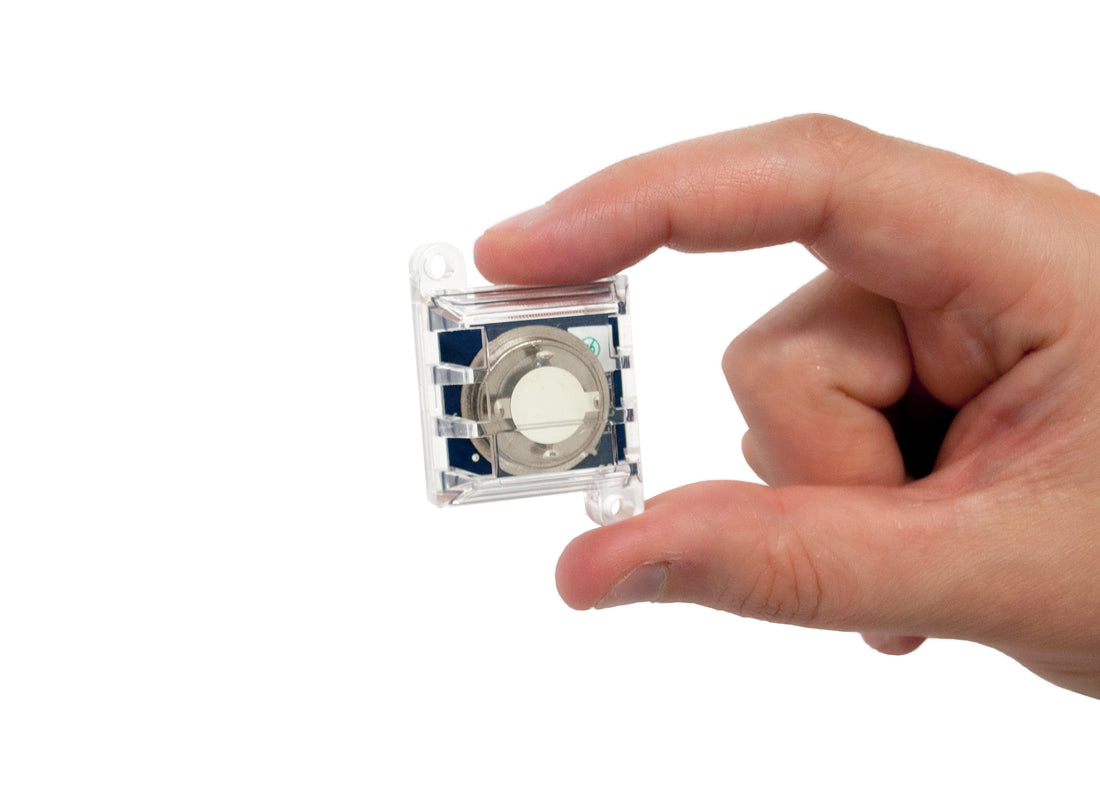

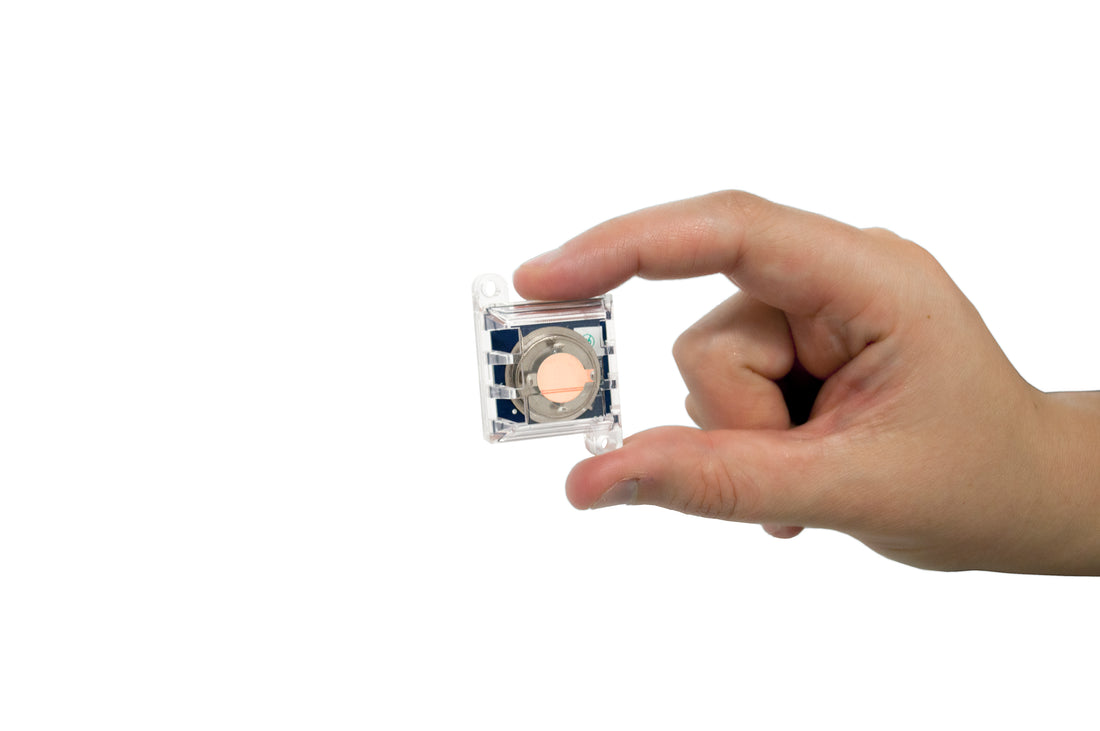

Our Corrosion Coupons measure the reactivity rate over a 30-day period and can be a helpful tool for initial diagnosis or continued monitoring in low risk environments. Additionally, Purafil’s Coupon process is uniquely digital from registration to reporting, making your monitoring process a breeze.

For quicker results, Purafil’s OnGuard Monitoring Units provides the corrosive air data you need in real-time to better understand the source of corrosion in your environment — including the ability tracking spikes and peaks in the digital log.

Looking for a complete tailored solution? Purafil’s trusted team of experts are here to help. Contact us today to learn more about your options for combating a corrosion problem in your facilities.

0 comment